Production technology and equipment installation and maintenance of aerated concrete

Aerated concrete production process is currently a relatively mature set of brick technology, composed of fully automatic equipment, four or five people can be completed, investment costs less, greatly improve the work efficiency, investment profits are also greatly increased.

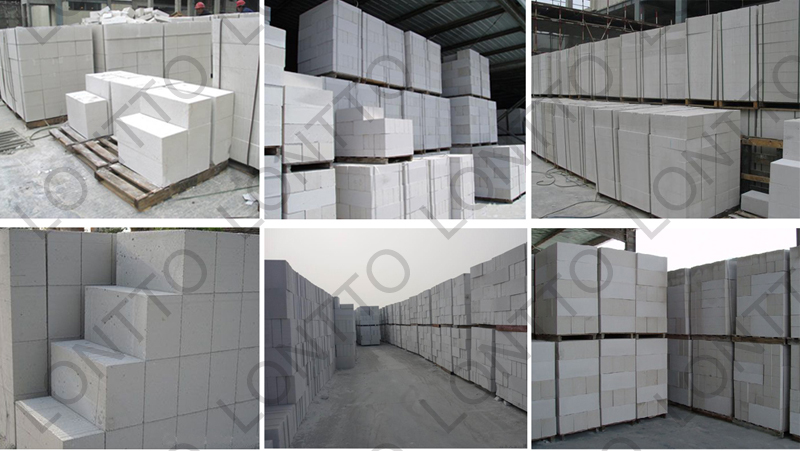

The concept of aerated concrete is to use silica material including pulverized coal, mineral powder and sand and so on, there are calcareous materials, cement and lime and other raw materials, and then mixed with forming agent, that is, the usual use of aluminum powder, through raw materials, mixer mixing, pouring, cutting and other series of process processing, can be made into homogeneous silicate products.

We see the bricks are very light, contains a lot of pores, hardness is also very large, so now greatly replace the firing of red bricks, which is today's most commonly used aerated concrete.

Aerated concrete is the advantage of the production of raw materials are rich, especially the use of industrial waste Fly Ash Bricks Making Machine as raw materials, which has reached the control of environmental pollution, but not to destroy arable land, creating a great social effect and economic effects, but also the most ideal wall materials, At present, aerated concrete production technology has been highly supported by the state, including a lot of preferential policies, tax policies and other strong support, it can be said that the prospects are very broad.

Aerated concrete production technology mainly includes the raw material storage and feed of aerated concrete blocks, the treatment of aerated concrete block raw materials, the addition of gas batching, stirring pouring, the initial feeding and cutting of aerated block, and the vapor pressure of aerated block to finished product.

Raw material transport to the plant after the concentration, to use when using the loading truck into the bucket, which needs to be noted that cement raw materials to be installed in the cement inventory, chemical supplies such as magnesium powder and other raw materials to be placed in the chemical library or aluminum powder library, the use of the time to separate shipment.

The chemicals are stored in a suitable proportion and are made into a solution of a certain concentration.

Aerated concrete production process is full automatic production line, as long as the material transported to the conveyor belt can be made after the finished product.

Aerated concrete production process It is also important to maintain equipment in the installation of the time we must ensure that all equipment convergence is good, to be in the same plane, to avoid equipment instability.

To establish a maintenance record of equipment, the maintenance of equipment regularly do a good job.

What are the characteristics of the hydraulic block forming machine?

Block forming machine can be said to be a new type of machine, mainly the production of block and cement brick machine.

and the block forming machine can be divided into hydraulic block forming machine, cement block forming machine, automatic block forming machine, concrete hollow block forming machine.

Understand the characteristics of hydraulic block forming machine, the following detailed explanation.

1. Can produce a variety of types of bricks.

The hydraulic block forming machine has a variety of switching modes, which can realize the function of one machine.

Can produce the standard brick, the hollow brick and so on more than 10 kinds of types of bricks.

In general, the hydraulic block molding machine model is the production of standard brick mode.

If you want to produce other types of bricks, you need to press the toggle button conversion mode.

2. The brick speed is quick.

The use of Hydraulic block molding machine, can be achieved every second out of brick, and this efficiency is currently the highest.

It belongs to the speed of the block forming machine.

and the use of Hydraulic block molding machine, can be achieved every 25 seconds to produce 26 bricks.

3. Can produce more superior products.

Because the interior has four pillars, the four pillars in the hydraulic block forming machine inside is to play a stable balance of the role, so that the mold to obtain a more reliable balance, when the mud in the mold production, can be produced with a large density, small block burrs, more neat clay brick making machine price in india products.

4. The use of hydraulic block forming machine is more in line with the concept of advanced technology.

It is used in the reducer technology is the world's leading level, and at this level of the hydraulic block molding machine, produced by the bricks can make customers satisfied.

We need to know that the use of bricks in the construction industry is a supporting role, only the density, strength enough to be safe.

And these high-quality bricks, they need to rely on the advanced technology system.

5. Simpler operation, more convenient maintenance and repair.

Generally speaking, this kind of Hydraulic block molding machine All has the automation execution procedure, only needs to hit one this procedure, can produce automatically, does not need the manual operation.

The hydraulic block forming machine has the characteristic that can support it in the block forming machine profession development condition.

The above features, not only the hydraulic block molding machine has, as well as other block forming machine also has.

Compared with other block forming machine, hydraulic block forming machine is different from its use principle.

Application characteristics and precautions of pouring machine in aerated block equipment

Pouring forming molding of pouring Brick Making Machine Price List is a special process of aerated concrete difference and other kinds of concrete.

In this process, the bubbles are produced by chemical reaction of aluminum powder, formed and fixed under the specific conditions of aerated concrete slurry, and become a uniform pore structure filled with concrete interior space, which has a casting stability problem.

Application characteristics of pouring machine and matters needing attention:

To achieve the casting stability of pouring machine, the key lies in the adaptability of aerated concrete slurry to aluminum powder forming process, the aerated concrete slurry produced by Lontto Machine can provide the conditions of bubble generation and stability in the forming stage of aluminum powder, and when the forming of aluminum powder is finished, the bubbles can be kept in the slurry well in time. Until the slurry hardened to form a porous aerated concrete body, in essence, the thickening of slurry and the forming of aluminum powder are suitable.

When the viscosity of slurry is not up to the forming speed of collapse mode, when the slurry thickening too quickly forming not comfortable, produce breath, bubble uneven, bubbling, body shrinkage and sinking.

When the pouring process successfully achieves the forming expansion to form a good pore structure, it can be determined that the pouring is stable.

Conversely, this casting is not stable or unstable.

The aerated concrete slurry, which can be poured stably, is considered to have good pouring stability.

Conversely, this aerated concrete slurry pouring stability or poor.

An important index of the mixture ratio and production process of aerated concrete is to improve the pouring stability of aerated concrete slurry.

is an important technical key to improve the production quality of aerated concrete.

It plays a decisive role in the production of aerated concrete, which has a significant impact on the performance of products, production efficiency and production of the next process.

How much do you know about the advanced technology of the brick machine?

At present, with the development and progress of the construction industry, the demand for building materials has been expanding continuously.

Now in order to meet the construction industry for the large-scale demand for brick materials, such as specialized production of bricks and mortar machine equipment is born.

Brick machine equipment is a specialized production of brick machinery and equipment, has a very wide range of applications.

What are the main aspects of the state-of-the-art of brick-and-mortar equipment? Follow me below to understand.

First of all, brick machine equipment is very environmental protection, little pollution, it is mainly stone powder fly ash gravel slag slag, etc. as raw materials, so as to produce the necessary cement bricks and other products.

Brick machine equipment can make the waste can be used again, so that the resources are reasonably configured, to the maximum extent to achieve the conservation and utilization of resources.

Thus promoting the effective protection of the environment.

The second brick machine is very rich in kind, can meet the different needs of people, so that people can choose the most suitable type of brick machine equipment.

According to the different product materials, can be subdivided into cement brick machine fly ash brick machine and clay brick machine these specific categories, according to the different production process can be divided into Hollow Block Making Machine brick machine and concrete brick machine and other specific types; According to the different degree of automation, can be subdivided into automatic brick machine Semi-automatic brick machine and manual brick machine These three kinds of specific classification.

The third brick making machine has the advanced performance of stable production efficiency, and it is very reliable and stable in the production operation, and will not appear the poor performance of equipment production speed or fast or slow, and has excellent performance.

In addition, brick machine equipment also has the advantage of high production efficiency, can meet the specific needs of large-scale production of brick products.

The four brick machine equipment also has the work noise small structure compact the advantage performance, not only can give the people to create a quiet operation environment, will also greatly save the space to occupy the land, has brought many conveniences to the people's life.

This shows that the brick making machine equipment has a wide range of advanced embodiment, it is worth our attention and choice.

The current brick machine equipment has become the main expert in the production of brick products, has been more and more widely used.

And the type of brick machine equipment classification is diverse, can give us more opportunities to choose.

How much does it cost to buy a cement brick machine? Price is not expensive?

The price of cement brick machine is not expensive? This is not a secret, can not tell the matter, of course, the different cement brick machine suppliers will be out of the same offer.

No matter what kind of equipment to buy, prices can always affect the hearts of consumers.

In order to better put into the cement production line to use, naturally to buy a high-quality, reasonably priced equipment.

How much does it cost to buy a cement brick machine? Also depends on the buyer's actual use conditions, take the site, it directly affects the cement production operations and patterns.

If it is 1-2 acres of operating range, you can buy QT-12 such a small cement brick block making machine for sale, the advantage lies in low investment, quick results, comprehensive market prices generally in between 8000-40000, now buy, about 2 weeks can be completed installation work, can be put into production.

If it is 3-4 acres of operating range, Lontto machine I give the proposal is can buy QT-13 model, investment cost than above said to be one times, but this can contain a series of auxiliary equipment, such as into the board machine, conveyor, mixer, forming machine and so on.

If it is 5-6 acres of operating range, Lontto machine Machinery Company recommended that you buy QT-14 models, investment 15.16 million, the ancillary equipment contained in accordance with the above, but here the basic equipment are fully automatic type, intelligent operation is more conducive to production, saving a lot of manpower and material resources.

If it is 7-8 acres of operating range, the recommended model is obviously not appropriate, as well as the choice of QT-15 cement brick machine, the total investment in 200,000-230,000.

Due to the large site, the need for a certain batching bin and automatic palletizing machine.

If it is more than 10 acres of operating range, QT-16 cement brick machine more suitable for some, the market total investment price is also the most expensive, up to 300,000.

Here, I think we have a good understanding of the market price of cement brick machine, the key depends on your investment ability.

Lontto machine I suggest, we can not because of cheap and listen to small manufacturers, after all, their product quality is not guaranteed, may have adverse effects on the future production.

hereby indicate that the above is only Lontto machine me according to the current cement brick machine supply market comprehensive analysis, as for lontto machine machinery can provide what type, corresponding to what kind of price, you need to inquire Lontto machine customer service.

The maintenance and maintenance of the brick making machine of building rubbish is best timed

Want to ensure the quality of building garbage brick machine, that in the ordinary work process, need to do the corresponding maintenance and maintenance work, after all, do not do this part of the work, it is easy to lead to work problems.

What can be done to ensure the actual effect of the work? In fact, from the following aspects to ensure that the effect of the work, let us in the construction of garbage brick machine in the process of use, as far as possible not to appear difficult.

Inspection must be timed to want to understand the construction waste brick machine equipment may appear in the process of the problem, it must be necessary for the equipment to do the corresponding inspection, only the various aspects of the inspection in place, to know the problem of building garbage brick machine.

Of course, in doing this part of the inspection process, it should also be noted that it is necessary to do the appropriate work, only this part of the work can be fixed time quantitative, after all, the time to understand the construction of garbage brick machine What kind of problems can be avoided because of a long time did not do the inspection, resulting in equipment problems.

Maintenance must be carried out in a comprehensive way, and of course it should be noted that the corresponding maintenance of construction waste brick machine work must be comprehensive, if not comprehensive, may be some maintenance place did not do well, this will undoubtedly directly affect the construction waste brick machine actual use effect, and at this time should pay attention to what kind of problem? Before maintaining the building waste brick making machine, we need to put the maintenance of the place are sorted out, to see where the maintenance is necessary to do, from where to do, how to do to ensure the use of the effect, are in the construction of waste brick machine maintenance process, need to pay attention to things.

Maintenance must be very meticulous of course, the corresponding maintenance work is also needed to do a good job, but in the process of doing this part of the work, we need to pay attention to a point is the need for meticulous, if the meticulous aspects of the work did not do well, may be a number of details of the problem, leading to the overall construction of garbage brick machine appearance of quality problems, Finally affect the use of construction waste brick block making machine machine effect.

Meticulous work needs from the construction of garbage brick machine itself characteristics, for the characteristics of all aspects of the details are done to really solve the problem of equipment.

So want to solve the construction waste brick machine use problem, the corresponding maintenance work must be done well, otherwise it is difficult to ensure the final effect of work, also can not ensure that the work in the use of the process, do not appear problems.